If you’re one of the growing numbers of people enjoying the benefits of CBD oil, CBD capsules or topical creams, you’re no doubt already aware of how CBD can boost your well-being and help promote a healthy balance.

Most CBD users know that CBD is derived from the hemp plant, but not many know how this beneficial supplement goes from plant to bottle.

But, if you’re curious about how things are made, you may have asked yourself, how is CBD extracted?

There are a number of different ways to extract CBD from hemp plants, each with its own pros and cons.

So, let’s investigate:

- How CBD oil is made in the UK

- Why CBD extraction methods matter

- What happens after CBD is extracted

Later we’ll go over each CBD extraction method, but first, let’s start with the basics

In this guide:

How is CBD made?

CBD is a type of cannabinoid, a kind of compound that is only found in cannabis plants.

So, simply put – CBD oil is made by extracting CBD cannabinoids from hemp plants.

CBD can be extracted from any kind of cannabis plant that contains high enough concentrations of the cannabinoid. This means that CBD can technically be derived from both hemp and marijuana.

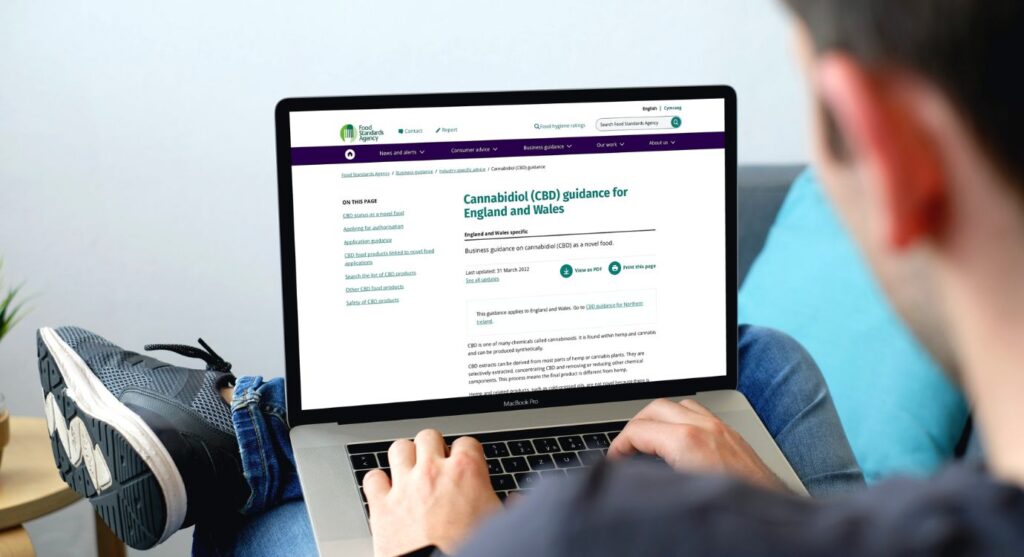

However, for CBD to be legal in the UK, it has to be derived from specific types of industrial hemp.

Read more: Hemp vs marijuana

How is CBD extracted?

So, how exactly does this extraction work?

CBD is extracted by only separating the CBD compound from a cannabis plant while also isolating it from other cannabinoids that are present, including THC.

Separating CBD from THC, the famous psychoactive cannabinoid, is one of the most important parts of the CBD extraction process.

This is because, for CBD to be sold legally in the UK, it has to contain low levels of THC.

Read more: CBD vs THC

Following extraction, the CBD oil is further refined and purified to create different types of CBD such as full-spectrum CBD, broad-spectrum CBD, or a CBD isolate.

The most common refining process is called “winterisation”. This is when residual solvents, chlorophyll, waxes and lipids are stripped from the mixture to create the final CBD product.

However, other refining processes are also becoming increasingly common, particularly CBD distillate, whereby the raw CBD mixture is heated to isolate compounds.

After the CBD has been refined, it needs to be tested to determine the quality of the CBD extraction. Testing determines the exact quantity of CBD and other molecules present in the extraction.

After testing, the CBD extract is combined with a carrier oil and additional flavourings and terpenes to create the final product.

10% off on your first order

Complete this one-minute quiz and find the right products for you.

5 CBD extraction methods explained

So, without further ado, let’s explore the different extraction methods and the benefits and drawbacks of each.

1. CO2 Extraction

The most common way to extract CBD from the hemp plant is using CO2 extraction.

The CO2 method is one of the most complex, advanced and expensive ways to extract CBD, but it also produces the most high-quality CBD.

Evopure’s products are made using this extraction method because it keeps as much of the plant as possible in its original form.

There are a few variants in the CO2 extraction process, but generally, this is performed using a machine called a closed-loop extractor.

A closed-loop extractor has three sections or chambers:

- Chamber 1

The first chamber has pressurised CO2, either in solid form or dry ice. - Chamber 2

The second chamber contains dry hemp materials: as the CO2 is pumped from the first to the second section, it takes on a state between gas and liquid, called “supercritical CO2”, extracting the cannabinoids from the hemp plant material. - Chamber 3

The mixture is then pumped into the third chamber, where CBD stays on the bottom of the chamber while the CO2 rises to the top, effectively extracting the CBD from the mixture.

The CBD is then put through a process of distillation to select the ideal cannabinoid profile.

Pros of CO2 extraction

- CBD products that are derived using CO2 extraction are typically highly concentrated, extremely safe and free from contaminants.

- This process results in a stable CBD product with a good shelf life as long as the CBD is stored correctly.

- Throughout the extraction process, it’s possible to select the optimum cannabinoid profile, limiting THC while ensuring other beneficial cannabinoids are retained.

Cons of CO2 extraction

- The main downside of CO2 extraction is that it is expensive and requires a large investment from manufacturers to set up the appropriate equipment.

- Most quality CBD manufacturers will use this process, but this is reflected in the price tag of the final product.

Read more: Why is CBD oil so expensive?

2. Liquid solvent extraction

Prior to the popularisation of CO2 extraction, CBD was often extracted using a liquid solvent.

There are a variety of different solvents that can be used to extract CBD from the cannabis plant, including ethanol, butane, hydrocarbon, propane or isopropyl.

This method works by dissolving the waxes in the cannabis plant in order to release the cannabinoids, including CBD.

Finally, the trimmings and the solvent are evaporated, leaving behind the concentrated cannabinoid solution.

Pros of solvent extraction

- It is cost-effective. In fact, it’s one of the cheapest ways to extract CBD

- It is relatively easy to do.

- The process is much quicker than other extraction methods.

Cons of solvent extraction

- This process can be quite dangerous as it involves using liquids that are highly flammable.

- Since the process breaks down the plant waxes, it releases not only cannabinoids but also other components in the cannabis plant. This includes chlorophyll which has a bitter taste and can therefore make the CBD taste bitter too.

- If not done properly, this process may leave toxic residues behind that contaminate the final product. In order to avoid this, the manufacturer must ensure that the solvent is completely evaporated during the process.

- Studies found traces of petroleum residue or naphtha hydrocarbons in some CBD products that were extracted using solvents.

Read more: What does CBD oil taste like?

3. Alcohol extraction

Alcohol extraction is a popular and safer alternative to toxic and carcinogenic hydrocarbons.

Similar to solvent extraction, the alcohol separates the plant compounds from the plant material and then evaporates, leaving behind a mixture of cannabinoids, terpenes, flavonoids, chlorophyll and more.

A process of distillation can then refine this finished product. Ethanol is an effective solvent for extracting CBD compounds from cannabis plants without the risk of leaving behind harmful chemicals.

Pros of alcohol extraction

- This is a cheap and effective method for extracting CBD. It’s also possible to do this at home with very little specialist equipment.

- The result is a product that is very close to nature, with a wide profile of cannabinoids, terpenes and other beneficial plant compounds.

- If the flavour isn’t important, this is a great method for producing CBD products like topical CBD or CBD capsules.

Cons of alcohol extraction

- Ethanol and other natural solvents are more likely to extract chlorophyll at the same time as cannabinoids, leading to that bitter taste that we mentioned earlier.

- Ethanol may be left behind in the finished product, making it unsuitable for those who do not drink, such as Muslims.

Read more: Is CBD oil halal?

4. Olive oil extraction

Olive oil can also be used as a natural solvent to extract CBD from hemp plants.

In fact, this is believed to be the method that was first used to derive CBD.

The process is similar to the liquid solvent extraction methods we described above, but there are some important differences.

Most notably, the raw plant cuttings and flowers must first be heated to a certain temperature and for a set amount of time. This activates the cannabinoids, including CBD, through a process known as decarboxylation.

After heating, the plant pieces are soaked in olive oil. This mixture is then heated once more in order to extract the CBD compounds.

Olive oil is most commonly used, but the same process can be used with other natural oils such as MCT oil, coconut oil and, fittingly, hemp seed oil.

Unlike solvents such as hydrocarbons and ethanol, olive and other natural oils do not have a low boiling point. This means they cannot be evaporated off like those solvents and remain present.

However, the specific heating process activates the cannabinoids, including CBD, making them ingestible by the human body.

Pros of olive oil extraction

- It’s safe, easy and affordable.

Cons of olive oil extraction

- Since the oil does not evaporate, the result is a CBD and olive oil mixture that has a lower CBD concentration compared to some other extraction methods.

- The finished product has a short shelf life, so it wouldn’t be suitable for mass production.

- The finished product must also be kept in the dark, which isn’t ideal for most consumers.

5. Steam Distillation

Another way to separate or extract CBD oil from the hemp plant is by using steam.

This is an ancient method that has been used to extract essential oils from various plants and flowers for hundreds of years. More recently, it has been used to extract CBD from hemp plants.

In this method, hemp plant fibres are placed in a glass flask. Steam is passed through the flask, breaking down the plant fibres and extracting the beneficial compounds from the waste material.

The vapours are captured within the glass flask. From there, they move into a condenser tube, and as they cool, they condense, turning into CBD oil and water.

Finally, the oil and water mixture is distilled, separating out the CBD oil and the water.

Pros of steam distillation

- Steam distillation is a very safe method of extraction without the risk of leaving behind dangerous contaminants.

- This method can be carried out at home with some specialist equipment.

Cons of steam distillation

- This method is much less efficient than other CBD extraction processes, requiring a much larger amount of raw hemp material to produce the same amount of CBD concentration.

- The process has to be carried out quite precisely, ensuring the correct temperatures to avoid damaging the extract or damaging the chemical properties of the cannabinoids.

Which CBD extraction method is best?

It is difficult to say which method of CBD extraction is the best because each process has its pros and cons.

It could be argued that CO2 extraction is the superior method because it produces the highest quality results along with a very safe product.

For this reason, this is the method used by most leading manufacturers and recommended by many CBD sites and publications.

Why are CBD extraction methods important?

So know we know how CBD is extracted – but why should you care?

Different companies use vastly different CBD extraction methods, meaning that not every CBD product is the same, nor does it deliver the same benefits.

Read more: CBD benefits

Understanding the different CBD extraction methods is, therefore, very important.

It will allow you to make an informed decision when you buy CBD products: by checking how the CBD oil was extracted and fully understanding the implications of that information.

Different companies may choose a particular extraction method because it produces a high-quality product, or they may be driven by economic motives.

Therefore, knowing how your CBD is extracted, will help you choose quality CBD products and prevent you from paying too much for sub-par CBD.

Summing up

Understanding the extraction process will help you to understand the potential risks and rewards of any CBD product you take.

While CO2 extraction might be the most popular process, it’s important to be aware of other methods when purchasing CBD products.

This could help you to avoid paying too much money for a product that promises to be “artisanal” or “small batch”, which is actually just produced using inferior processes.